This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website, storing information about your account with us and helping our team to understand which sections of the website you find most interesting and useful.

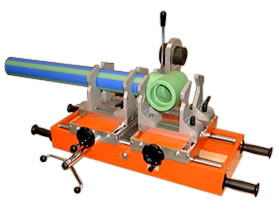

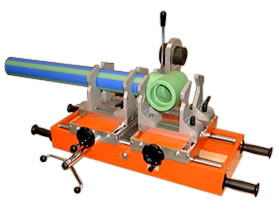

Butt Welding Machine 40 - 160mm

Butt Welding Machine 40 - 160mm

REMS SSM 160K butt welding machine is a powerful, proven, easy-to-carry compact machine. Ideal for sanitary installations and installations of drain pipes, chimney reconstruction with PVDF pipes.

REMS SSM 160K butt welding machine is a powerful, proven, easy-to-carry compact machine. Ideal for sanitary installations and installations of drain pipes, chimney reconstruction with PVDF pipes.

Additional Information

Features:

- Light and compact.

- Heating element according to DVS.

- Electronic temperature control.

- High-quality PTFE coating.

- Powerful facing cutter.

- Closed facing cutter housing.

,

These are the recommended PPE required for this product.

Eye Protection

Hand Protection

Hard Hat

Foot Protection

Ear Protection

Related Products

Hire

Uniprep 1 Rotary Scraping Tool 90-400MM

The Uniprep 1 Rotary Scraping Tool offers a lightweight die cast aluminium body and 4 edge tungsten scraping tip.

Hire

Angle Clamp

This lightweight aluminium jaws (Code FCA) holds pipe sizes 63-180mm without the need for reducing liners. When coupled together with the angle maker you have the versatility of a positioning clamp to hold pipe in 45° and 90° bends. The quick opening handle and the patented centering system allows you to install the clamp easily over the pipe until the weld process has finished.

Hire

Aquatherm Bench Machine Pack 50 - 125mm

The Aquatherm Welders are designed for jointing pipes using “Socket Fusionâ€. Using an electrical heater plate with add on heater brushes for each individual tube size.

Hire

Hand Held Machine (Hot Plate) 40 - 75mm

Hand Held Fusion hot plates provide a very simple, easy to use way of manually butt welding HDPE pipework.

Hire

HPPE (PE100) Fusion Welder 16 - 315mm 40V

Electrofusion units for use on various PE Pipping system.

Please ensure any person using this equipment has received training and has read the instruction manual and is aware that pipe clamping is required during the welding process.

Hire

Rems Butt Welding Machine 90 - 315mm

789-rems-butt-welding-machine-90-315-mm

REMS SSM 315RF butt welding machine is a Powerful, easy-to-carry high-performance machine. Ideal for sanitary installations and installations of drain pipes, chimney reconstruction with PVDF pipes.